Reverse Logistics Management

As supply chains grow in complexity through globalization and digitization, reverse logistics has become a critical component for companies navigating the challenges presented by e-commerce. If you require a 3PL reverse logistics partner, choose IronLink to manage your supply chain more efficiently and effectively. Our reverse logistics services can provide significant cost savings and increase in consumer satisfaction.

Returns Management: What Is Reverse Logistics?

Providing customers with the option to return products is a prudent business strategy. Reverse logistics refers to the handling of product returns by customers, reintegrating them into the supply chain. The

utilization of reverse logistics equips the company with a structured approach to oversee these returned items and reprocess them in an effective and sustainable way.

Get reverse logistics fulfillment with IronLink Logistics. Call our return management experts today: 833-214-0220.

The Benefits of a 3PL Reverse Logistics Management Company

In the post-pandemic era where one-click purchasing has become a consumer norm, 3PL reverse logistics plays a crucial role throughout the supply chain. As supply chains evolve into more intricate and circular structures, reverse logistics enhances consumer flexibility and product availability.

A streamlined product return process, facilitated by an experienced reverse logistics partner, becomes a catalyst for increased online purchases, reducing shopper hesitancy. Satisfied consumers are more likely to make larger and more frequent purchases, positively impacting businesses despite the inevitable returns. By meeting the demands of today’s consumers, a robust reverse logistics program adds value to the business.

The Reverse Logistics Process: The 7 R’s Of Reverse Logistics

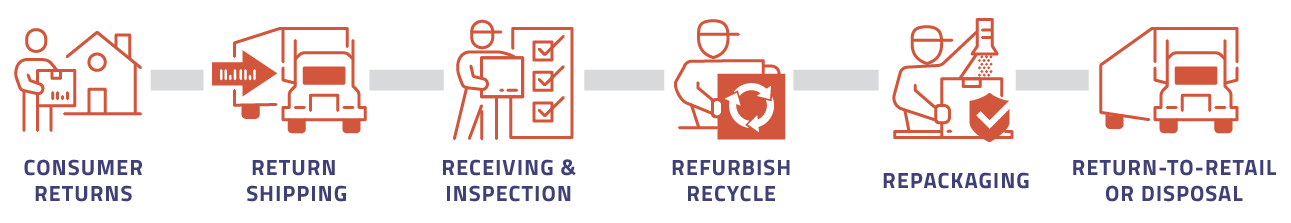

The reverse logistics process comprises several crucial phases, known as the 7 R’s of Reverse Logistics. This process is the foundation of an effective and efficient procedure for handling returned goods in the supply chain. While the actual process may vary across businesses and industries, the fundamental procedural components remain consistent.

Consumer Returns

Consumer returns in reverse logistics begins with a clear, organized method of initiating the return process. Standard operational procedures are critical to the effectiveness of the application of reverse logistics fulfillment. To be effective, businesses must clearly share, in detail, the specific steps to initiate their return procedure to their customers. A critical step early in the return process is establishing a return material authorization (RMA). RMAs can significantly reduce cost in the return process.

Consumer returns are usually divided into three categories:

- Products arrived damaged.

- Products arrived defective.

- Products failed to meet the consumer’s expectations.

Categorizing the types of the return is essential for assessing the returned product and selecting the most feasible outcome for the return once it has departed the customer. Choose the best reverse logistics company to discuss a strategy to optimize your business’s supply chain.

Return Shipping

In developing an effective return process, RMAs are frequently followed by a return shipping label. The return shipping phase of reverse logistics is vital for strong customer service. Businesses with successful reverse logistics procedures will have a detailed and clear process for the customer to follow to send the product back. Consumers left to find their own carriers and packaging can easily become frustrated and disenfranchised with the brand.

For the business involved, working with a 3PL reverse logistics partner can streamline the returns process, increasing consumer satisfaction and eliminate unnecessary costs.

Receiving and Inspection

Once the returned item has been received by the business or organization, inspecting the item is vital for the remaining steps in the reverse logistics process. A full-service 3PL company can streamline reverse logistics by offering value-added third-party warehousing services to quickly assess the returned item and proceed to the next phase of the process.

During inspection, it can be determined whether the returned item will then be refurbished, recycled, or repackaged for resale. It is critical to keep returned products in continually motion through the supply chain at all times. This fluidity eliminates unwanted costs and waste.

Repair/Refurbish/Recycle

As items are inspected and moved to their appropriate destination, items deemed repairable are often damaged products. Once repaired, these items are then returned to the original customer. Similarly, products that are refurbished are also returned to a ‘new’ condition and then resold.

Returned items that cannot be returned to like-new condition may then be recycled. Recycling presents not only sustainability for the business, it can also equate to significant savings in salvaging valuable components from the returned product. For this phase of reverse logistics to be effective, it’s essential to have efficient product tracking systems and inventory management at hand.

Repackaging

Upon inspection, if items are not damaged or in need of repair and were returned due to customer dissatisfaction with the product, these items will then move to the repackaging step in the reverse logistics process.

A commercial 3PL warehouse with value added services, such as IronLink Logistics, will be able to provide custom repackaging services. In this phase, repackages and prepares the item for return to the self to be resold. Repackage products should move quickly through the reverse logistics process so that they can be returned to inventory and minimize lost revenue.

Return-to-Retail or Disposal

Return-to-retail or disposal of a returned item is inevitably the final phase of the reverse logistics process. A fortified supply chain enables on-time processing of returned items, enhancing overall efficiency. This efficiency not only fosters higher consumer satisfaction but also reduces unnecessary expenses associated with returns.

Integrating circular economics into reverse logistics can yield substantial advantages for businesses. Improving sustainability through recycling and proper disposal offers multiple benefits by optimizing your supply chain and cutting down costs.

IronLink: Your Reverse Logistics Expert

Reverse logistics fulfillment, with the right 3PL reverse logistics partnership, can offer great rewards to your business. Utilizing the expertise of a full-service 3rd party logistics company can eliminate many of the challenges your company is faced with when creating an optimal supply chain strategy.

Reach out to an IronLink Logistics reverse logistics specialists to discover how our value-added services in reverse logistics and warehousing can simplify your returns process and maintain your business at peak efficiency.