Material handling is a critical component in logistics and is essential not only in the warehousing sector, but also has a wide range of uses across a large variety of industries. For such companies, material handling is the key to the success and safety of their operations. Material handling is ever-present in the distribution process through the transport of goods, the working operation, and transporting of products to the end customer. For warehouse management systems, material handling is the movement, protection, storage, and control of materials and products. The process of material handling can utilize manual, semi-automated, and automated systems and equipment.

IronLink Logistics continues to lead in the 3PL industry by keeping our systems running with the latest logistics technology to operate at maximum efficiency and hold our competitive edge in the industry. Request a logistics quote to learn how we can optimize your warehouse operations.

The Importance of Material Handlers in the Warehouse

By the year 2025, the global material handling market is expected to surpass $127.26 billion. As consumers continue to rely on on-line shopping and home delivery services, the demand on industries relying on global supply chains is vital. This means the reliance on material handlers is very high.

Warehouse material handlers move, redistribute, and retrieve items within the commercial warehouse. They also can be responsible for shipping and restocking inventory. Warehouse material handlers make sure the warehouse infrastructure is working correctly and safely. They keep the supply chain moving and ensure the success of the business. Efficient and timely order fulfillment is a must in maintaining customer satisfaction.

The Importance of Material Handlers in the Warehouse

By the year 2025, the global material handling market is expected to surpass $127.26 billion. As consumers continue to rely on on-line shopping and home delivery services, the demand on industries relying on global supply chains is vital. This means the reliance on material handlers is very high.

Warehouse material handlers move, redistribute, and retrieve items within the commercial warehouse. They also can be responsible for shipping and restocking inventory. Warehouse material handlers make sure the warehouse infrastructure is working correctly and safely. They keep the supply chain moving and ensure the success of the business. Efficient and timely order fulfillment is a must in maintaining customer satisfaction.

Warehouse Associate. A warehouse associate covers a large spectrum of duties within the commercial warehouse. These staff members can be assigned to unloading incoming shipments, taking inventory, picking and packaging shipments, and loading outgoing shipments.

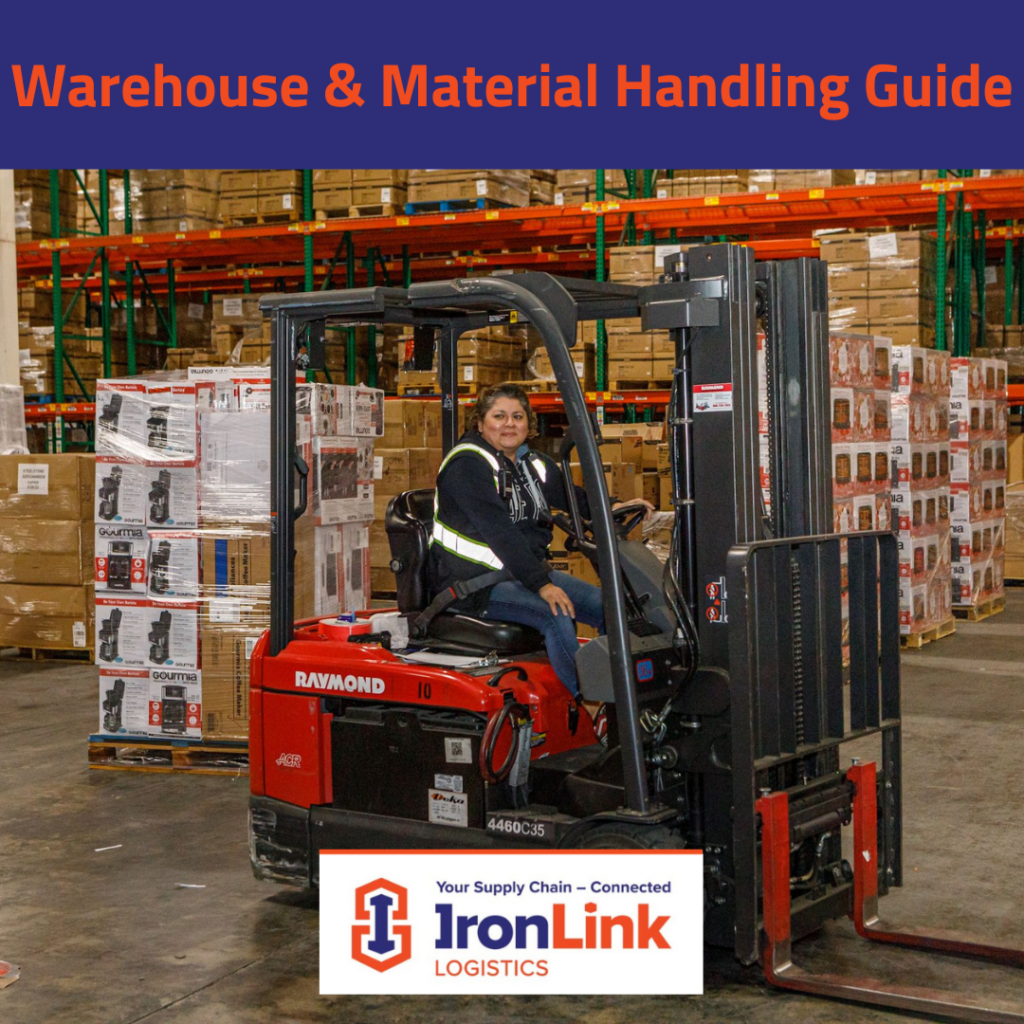

Forklift and Machinery Operator. These operators in the 3PL warehouse facility are responsible for unloading and moving incoming shipments to their proper places for storage while also moving the outgoing shipments to loading areas.

3. Warehouse Manager. A warehouse manager oversees nearly all operations within the warehouse. Shipping and receiving, inventory management, and machinery operation are all responsibilities of a managerial position within the warehouse.

4. Material Handler. Material handlers are responsible for the movement of goods throughout the warehouse. They restock inventory as it enters the warehouse and retrieve inventory from storage for shipping.

5. Shipping and Receiving Associates. Shipping and receiving associates ensure that both the incoming and outgoing orders are accurately received, processed, and shipped.

6. Warehouse Clerk. Warehouse clerks’ roles in the warehouse are to communicate with both customers and staff. Their responsibilities are centered around the orders and that they are properly processed and recorded.

7. General Laborer. General laborers in the warehouse are often responsible for janitorial and maintenance duties.

The warehouse staff must be a cohesive team to work in a safe and efficient manner. A strong warehouse management system increases the functionality of the team and provides strategies to create and continue high performance operations. IronLink understands the importance of a well-trained staff to provide value-added services for your warehousing needs.

Materials Handling Equipment

The material handling industry is projected to increase its Compound Annual Growth Rate (CAGR) 0f 5.5 percent. With the tremendous growth and demand placed on the materials handling industry, the advancement of new warehouse technology and 3PL automation are being implemented to keep up with the ever-changing consumer and market needs.

Four general categories exist for the classification of material handling: bulk systems, engineered systems, storage, and transportation. Material handling is critical to moving and storing materials and goods throughout the manufacturing, warehousing, and distribution process. Material handling equipment is categorized into three distinct parts.

- Manual Material Handling Equipment

Manual material handling equipment is powered and operated by humans. This material handling equipment moves and/or handles material by means such as lifting, pushing, pulling, and carrying. Some common types of manual material handling equipment are:- Hand trucks and trolleys

- Pallet jacks

- Carts

- Hoists and articulating arms

Manual material handling equipment offers both advantages and disadvantages to the warehouse. Manual equipment is usually smaller, lighter, and more versatile. This type of equipment is economical and requires no additional power sources, fewer maintenance issues, and smaller start-up costs. The main disadvantage is that manual equipment, being human-powered, can leave operators more apt to be injured.

- Motorized Material Handling Equipment

Motorized material handling equipment, while still requiring human operation, greatly improve the efficiency and productivity of the warehouse and reduce the risks of accidents or injuries to the staff. Major advantages are they significantly save time and offer greater mobility and agility in a logistics warehouse. The equipment comes in four categories:- Burden carries

- Platform trucks

- Industrial tuggers/tow tractor

- Personnel movers

Motorized material handling equipment is a low-maintenance and a durable solution to warehouse operational systems.

- Automated Material Handling

Automated material handling systems replace or reduce the need for manual material handling. It utilizes various forms of logistics technology for storing and retrieving products. Comprised of machine programming, robotics, and sensing technologies, automated material handling relies on computers and robots to move materials with exact precision. These types of material handling equipment can be sorted into the following categories:- Automated mobile robots

- Automated guided vehicles

- Automated storage and retrieval systems

- Automated conveyor systems

- Automated pallet rack systems

- Automated pick systems

Automated material handling equipment improves facility productivity while improving safety. As industry trends are aimed at increasing efficiency and productivity, integrating technology is essential to keep up with the demands on the industry. Read more about 3PL technology trends.

IronLink uses all forms of equipment to assist with your commercial warehousing needs such as cross-docking and transloading. Learn how IronLink can keep your warehouse goods moving; talk to an IronLink Logistics pro today.

The Importance of Commercial Warehouse Layout for Effective Material Handling

The layout of the warehouse can impact the effectiveness and the efficiency in material handling. By organizing and placing the processes in the warehouse in a logical sequence, material handling will become more productive and operating costs will decline. An effective 3PL warehouse layout can benefit the facility by:

- Increase warehouse capacity by maximizing and optimizing space.

- Increase productivity by speeding up picking while eliminating errors and bottlenecks.

- Decrease operational costs by having correct equipment and staff in their proper places and utilizing the best resources effectively.

- Increase workers’ safety by incorporating the proper safety products and accessories throughout the facility.

- Increase warehouse management by establishing a layout for success.

To achieve these successes in the warehouse, its layout should include areas designated for staging, storage, picking & packing, and dispatch of the products. The thoughtful and logical design of IronLink’s warehouses can directly increase the productivity of the facility.

What Are the Best Practices of Material Handling in the Warehouse?

When implementing a 3PL warehouse management system, several key components should be considered in its development. Material handling can impact all phases of a business’s operation. In the 3PL space, IronLink Logistics emphasizes several key components to optimize material handling in the warehouse. At IronLink we focus on:

- A plan that incorporates standardization and is derived from the organization’s goals and objectives.

- Keeping lean inventory that is simplified and identifies the ergonomics in the operation.

- Develop a systematic approach that organizes and unitizes materials and products.

- Strive to keep ahead of industry trends by going green and integrating automation.

- Continue to analyze and evaluate material handling equipment and costs.

Our 3PL warehouses are located along major ports on the east and west coast. Learn more about our IronLink Logistics commercial warehouse locations in California, New Jersey, and South Carolina.

Warehouse Services Near Me?

At IronLink Logistics, we strive to provide the best in 3PL warehousing services. We have the ability to incorporate the best in data capture, motor freight, and warehouse management systems. We are always growing and adapting to the logistics industry changes; we are currently migrating to a new warehouse management system that will keep IronLink as a leader in third party logistics.

IronLink provides the most competitive and efficient warehouse management systems. Increase your productivity by choosing IronLink for your 3PL needs. Contact us today at info@ironlinklogistics.com or call 833-214-0220.